Roller Mill Coal Grinder

- Description

-

The MPS(MP) type roller disc coal mill is a high-efficiency and energy-saving coal mill, suitable for grinding medium-hard materials such as bituminous coal, and can be widely used in the pulverizing systems of industries such as power, metallurgy, building materials, and chemicals.

Our company introduced a complete set of design, manufacturing, and inspection technology for three specifications of MPS roller disc coal mills from Babcock in West Germany in 1985. After digesting and absorbing the introduced technology, we independently developed a series of roller disc coal mill products ranging from MP1000 to MP2650, and have formed mass production, capable of undertaking the design and manufacturing tasks of any specifications and types of MPS(MP) type coal mills.

Performance parameters of MPS(MP) roller disc coal mill

Model MP1108 MP1410 MP1512 MP1612 MP1713 MPS180 MPF1814 MPS190 MP1915 MPF1915 MP2015 MPS212 MP2116 MPF2116 MPS225 MPS2217 MPS235 MPS245 MPS255 MPS265 Drawing Number K288 K289 K2810 K2830 K284 KB278 K2845 KB272 K2815 K2823 K2841 KB275 K282 K2824 KB277 K2847 KB274 Basic Output (t/h) 13.74 24 28.5 33.5 39.0 45.0 52.6 58.5 67.7 78.7 87.7 99.3 107.6 118.4 Primary Air Volume (kg/s) 4.39 7.73 9.10 10.70 12.46 14.38 16.75 18.55 21.65 24.74 27.91 31.43 34.53 37.79 Grinding Disc Working Diameter (mm) 1120 1400 1500 1600 1700 1800 1900 2000 2120 2250 2350 2450 2550 2650 Grinding Roller Diameter (mm) 870 1090 1170 1240 1320 1400 1480 1550 1650 1750 1830 1900 1980 2060 Grinding Roller Width (mm) 296 370 360 380 410 430 450 480 510 540 550 590 610 640 Motor Model YS135

M-4YMPS

450-6YMPS

500-6YMPS

450-6YMPS

450-6YMPS

500-6YMPS

500-6YKK

560-6Y0710-11-6 YMPS

500-6YMPS

560-6YMPS

560-6YMPS

560-6Y800-11-6 YMPS

630-6Motor Power (KW) 120 185 220 250 330 355 400 380 450 450 500 580 650 720 800 880 Grinding Disc Speed (r/min) 34.2 30.59 29.6 28.7 27.8 27.0 26.4 25.6 24.8 24.8 23.6 23.2 2.6 22.3 Mill + Separator Resistance (kg/s) 4350 5170 5420 5700 5980 6170 6380 6570 6770 6970 7060 7290 7450 7610 Separator Type SLK SLS SLK SLS SLK SLS SLK SLS SLK Sealing Air Volume (kg/s) 0.6 1.16 0.65 0.7 0.75 1.34 0.8 1.38 0.85 1.42 1.49 0.95 1.53 1 1.6 1.65 1.7 1.74 Normal Noise (dB) <85 Machine Dimensions (mm)

(Length × Width × Height)4500×

6000×

5507000×

5000×

63507000×

5000×

57309000×

6000×

81009000×

6000×

75007500×

5600×

81508700×

6000×

81508500×6000×8300 8400×

6000×

89001000×

6000×

83008000×

6000×

900010500

×6300

×970010000

×7000

×971110000

×7000

×990011000

×7100

×1000011600

×7200

×1080012000

×7500

×11500Machine Weight (t) 33.43 61.1 70.7 89.9 110.7 90.6 99.4 126.4 127.5 124 125 168.66 165.8 143.7 190 131.05 205.7 220.8 240.06 260.5 Machine Structure Description

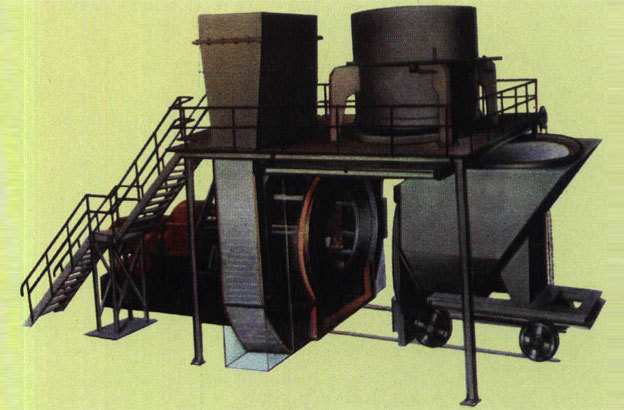

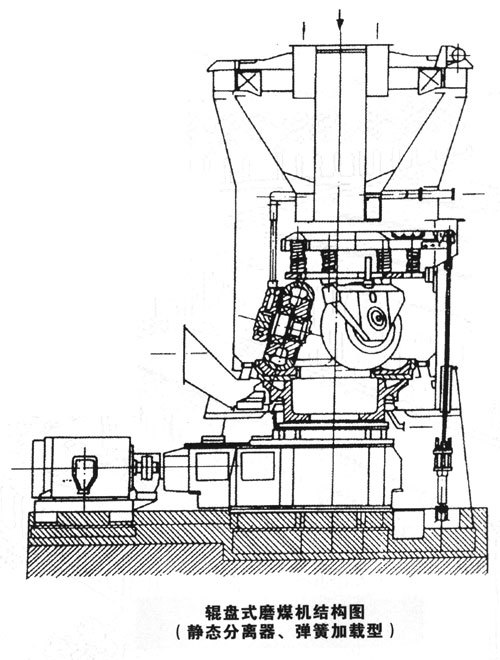

The MPS and MP type coal mills mainly consist of the foundation part, reducer, lower frame, middle frame, grinding disc, grinding roller, pressing device, separator, positive pressure air sealing device, steam purging device, and other components. They are also equipped with main motors, lubrication oil stations, hydraulic stations, and sealing fans, along with slow-speed transmission devices, special tools for installation and maintenance, ladder platforms, coal powder distributors, quick shut-off valves, and other supporting equipment for users to choose from.

Working Principle of Roller Disc Coal Mill

The MPS and MP type coal mills are a type of three-roller force-added coal mill, where the three grinding rollers are driven by the rotating grinding disc to perform grinding operations. The material to be ground falls onto the grinding disc through the central coal drop pipe, and the centrifugal force generated by the rotating grinding disc transports it to the grinding roller path for grinding. The grinding pressure is generated by springs or hydraulic pressing devices, and through a statically determined three-point system, the grinding force is evenly transmitted to the three grinding rollers, with the pressure transmitted to the foundation through the pressing system. The drying and transportation of coal powder are carried out using hot air. Hot air is evenly distributed around the grinding disc through the nozzle ring, drying the ground material and transporting it to the separator at the top of the mill. The coarse and fine powders are separated here. The fine powder is discharged from the mill, while the coarse powder is returned to the mill for regrinding. Some uncrushable materials in the material can be discharged through the discharge port at the bottom of the mill.

Key words:

Related Products

Get Quote