- Description

-

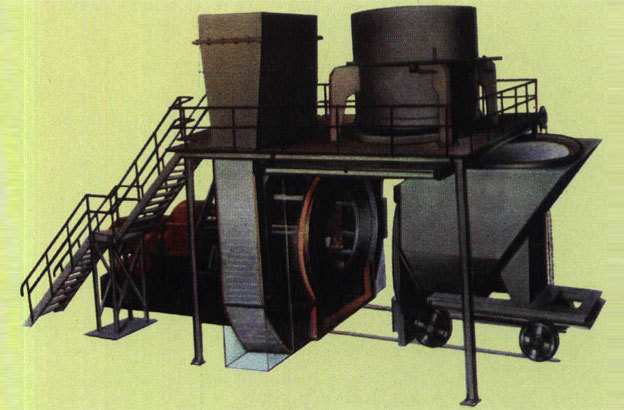

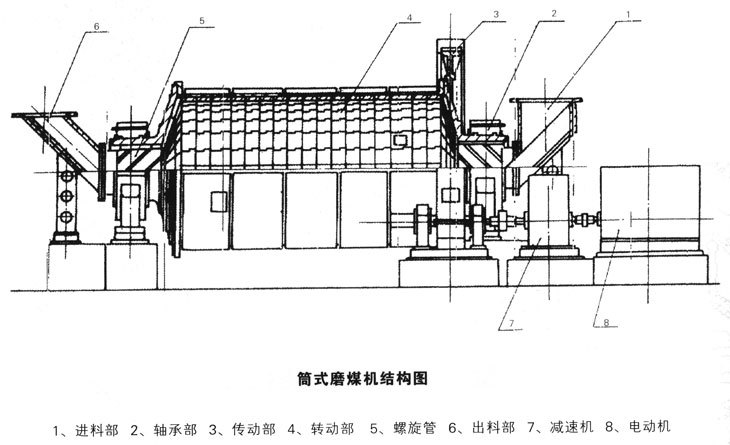

The tube mill is mainly used for grinding various hardness coal types in thermal power plants. It has characteristics such as a wide adaptability to coal types, reliable operation, and convenient maintenance.

In the 1980s and 1990s, through the introduction of technology from the French company STEININ-DUSTRIE and the American company FOSTER WHEELER ENERGY CORPORATION, and the digestion and absorption of the introduced technology, advanced technology was integrated into traditional coal mills, further improving the technical performance of the mills. A new series of coal mill products has been formed.

Tube Mill Technical Parameter Table

Model

SpecificationDrawing Number Cylinder has

Effective Length

(mm)Cylinder has

Effective Length

(mm)Mill

Speed

(r/min)Main Motor Maximum Ball Loading Capacity Inlet and Outlet

Size

(mm)Output

(t/h)Machine Weight

(t)

Excluding MotorModel Power

(KW)Speed

(r/min)Voltage

(v)Weight

(t)Filling Rate

(%))MTZ2126 K9311 21 2600 22.81 JS128-8

JS136-8155

145735

709380

300010 0.236 Φ600 600 4 37 MTZ2133 K9312 3300 JS136-8

JS137-8170

180735 380

300013 0.242 Φ650 650 6 38.5 MTZ2532 K9321 2500 3200 20.6 JS147-8

JS1410-8260

280735

7403000

600018 0.244 Φ750 750 8 51.1 MTZ2539 K9322 3900 20.77 22 Φ800 800 10 54.2 MTZ2935 K9336 2900 3500 19.34 YTM500-8 380 740 6000 26 0.239 Φ850 850 12 77 MTZ2941 K9337 4100 450 30 0.236 Φ850 850 14 80.7 MTZ2947 K9338 4700 560 35 0.24 Φ950 950 16 84.1 MTZ3247 K9345 3200 4700 18.52 YTM450-6 630 40 0.225 Φ1120 1120 20 101.8 MTZ3257 K9346 5700 18.54 YTM500-6 800 1000 50 0.194 25 109.2 MTZ3258 K9348 5800 800 50 0.213 25 112.1 MTZ3560 K9359 3500 6000 17.57 YTM630-1-6 1000 985 59 0.217 Φ1300 1300 30 142.0 MTZ3570 K93510 7000 YTM630-2-6 1120 69 0.218 Φ1350 1350 35 150.0 MTZ3865 K9363 3800 6300 17 YTM800-1-10 1250 595 75 0.20 Φ1574 1574 40 193.0

MTZ3872 K9364 7200 YTM800-2-10 1400 85 0.205 Φ1574 1574 45 199.5 MTZ3879 K9365 7900 YTM800-3-10

14301600 95 0.21 Φ1574 1574 50 207.0 MTZ3883 K362 8300 YTM1000-10 1000

×295 0.219 Φ1700 1700 50 219.7 MTZ3886 K9366 8600 YTM800-4-10 1800 105 0.213 Φ1574 1774 55 214.0 Working Principle of Tube Mill

The tube mill is driven by an electric motor through a pin coupling, a cylindrical gear reducer, and an open gear reduction transmission to rotate the mill's rotating cylinder. The mill cylinder is equipped with grinding media - steel balls. When the cylinder rotates, the steel balls are lifted to a certain height by the centrifugal force and friction, and then fall due to their own gravity. The coal inside the cylinder is crushed into coal powder by the impact and grinding action of the falling steel balls. The ground coal powder is sent to the boiler for combustion or stored in the coal powder bin by the pneumatic equipment of the pulverizing system.

Key words:

Related Products

Get Quote