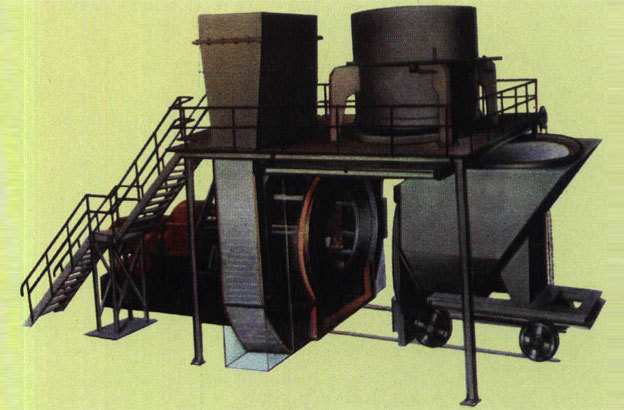

Double-in double-out coal mill

- Description

-

Our company introduced the direct-fired BBD double-inlet and double-outlet coal mill technology from the French company STEINNDUS TRIE in March 1989. The contract specified the transfer of four specifications of double-inlet and double-outlet coal mills: BBD3448, BBD4060, BBD4760, and BBD4772. In 1998, based on the physical properties of coal in our country, we further introduced the complete design, manufacturing inspection, and experimental research technology for two specifications of double-inlet and double-outlet coal mills: BBD3854 and BBD4366, to meet the needs of 100MW, 200MW, and 300MW and above thermal power generator boiler. In 1992, we also introduced four specifications of double-inlet and double-outlet coal mills: D10, D10D, D11, and D11D from the American company Forstor Wheeler, used for 300MW and 600MW thermal power generator boilers. After our company digested and absorbed the introduced technology, combined with China's national conditions, we localized its technical structure and developed a series of products in various specifications using a modular design approach, which have been well received by users. The first batch of products passed the 168-hour trial operation at once, creating a miracle in the trial operation of coal mills.

The BBD type double-inlet and double-outlet coal mill, with its unique design, has incomparable excellent performance. This type of coal mill has a wide range of coal types for grinding, stable output and fineness, reliable operation, high continuous operation rate and production efficiency, easy maintenance, long service life, large storage capacity, quick response to boiler load changes, great operational flexibility, low air-coal ratio, and is not affected by foreign objects. It is particularly suitable for grinding high ash content, high volatile content, and strongly abrasive coal types, as well as coal types with high fineness requirements and low volatile content.

The double-inlet and double-outlet coal mill has two symmetrical grinding circuits, which can operate in the following modes according to operational requirements: double-inlet and double-outlet, single-inlet and double-outlet, and single-inlet and single-outlet.

Double-inlet and double-outlet coal mill parameter table

Project Unit Model Specification of BBD double-inlet and double-outlet coal mill BBD2536 BBD2942 BBD3448 BBD3854 BBD4060 BBD4062 BBD4366 BBD4760 BBD4772 Inner diameter (lining inside) mm 2450 2850 3350 3750 3950 3960 4250 4650 4650 Cylinder length mm 3740 4340 4940 5540 6140 6340 6740 6140 7340 Diameter of double-cone separator mm 1600 1800 2100 2400 2900 2900 3050 3200 3500 Coal mill speed r/min 20.4 19 18 17 16.6 16.6 16 15.3 15.3 Main motor Power kw 280 500 800 1200 1400 1600 1800 2140 2550 Speed r/min 1000 Voltage v 6000 Maximum steel ball load t 20 32 48 67 76 88 97 106 127 Total weight (excluding the weight of the main motor, feeder, steel balls, and gate) t 119 196.7 235 236.1 242 245 263 Mill output Data provided based on standard coal: HGI=50, H2O=8%.

75% of particles pass through a 200 mesh screen.t/h 13 22 22 52 60 65 79 90 105 Working principle of the double-inlet and double-outlet coal mill

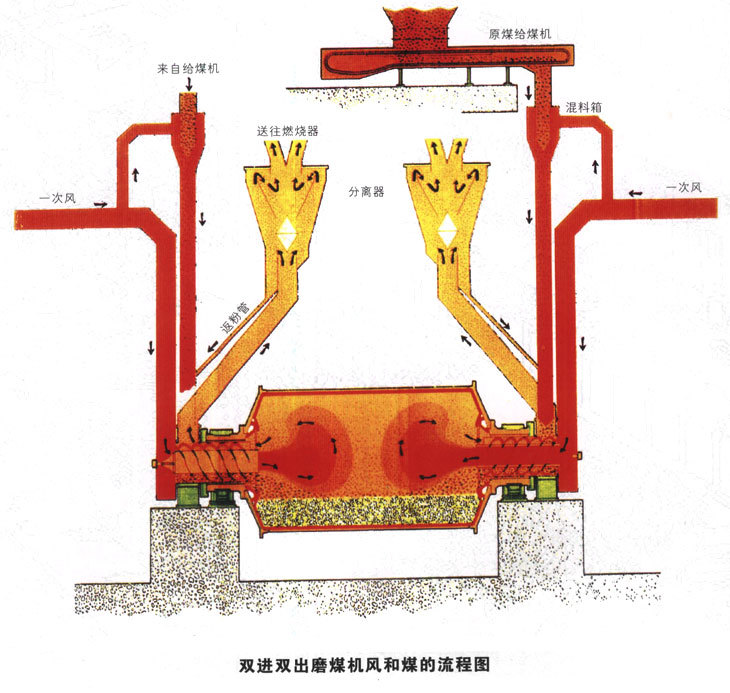

The double-inlet and double-outlet coal mill has two symmetrical grinding circuits, and its working principle is as follows:

Raw coal enters the drop coal pipe through a feeder that can automatically control speed, falling into the lower part of the conveying device due to gravity, and is sent into the coal mill's cylinder by the rotating cage. The rotating cylinder contains a certain amount of steel balls that grind the raw coal into coal powder.

Primary air enters the cylinder of the mill from the hollow pipes on both sides of the coal mill, drying the raw coal and coal powder, and transporting the ground coal powder through the annular passage of the cage to the separator above the coal mill. Unqualified coarse coal powder returns to the cylinder for regrinding, while qualified fine powder is sent to the boiler's burner.

Part of the primary air enters the mixing box, fully pre-drying the raw coal before entering the coal mill separator, mixing with the primary air entering the mill, and jointly completing further drying and transportation of the coal powder.

Key words:

Related Products

Get Quote